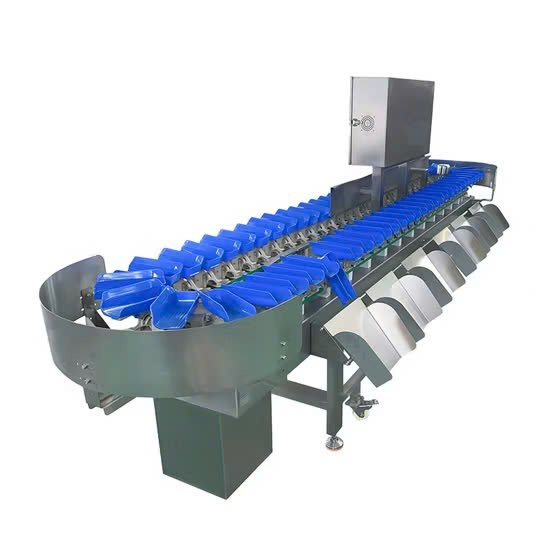

Shrimp Sorting Machine – RTG59 High-Precision Sorting Solution

The Shrimp Sorting Machine RTG59 by MenT Automation is a high-performance, precision-engineered system designed specifically for modern seafood processing lines. Built to deliver both speed and accuracy, the RTG59 ensures optimal sorting efficiency for shrimp and other small seafood items, helping factories improve product consistency and overall productivity.

With a sorting capacity of 170 products per minute, the Shrimp Sorting Machine provides outstanding throughput while maintaining excellent accuracy. The integrated 12-inch full-color touchscreen panel allows operators to easily control every parameter of the machine, monitor performance in real time, and adjust settings quickly to match production demands. This level of control makes the RTG59 a reliable solution for seafood factories seeking automation with minimal downtime.

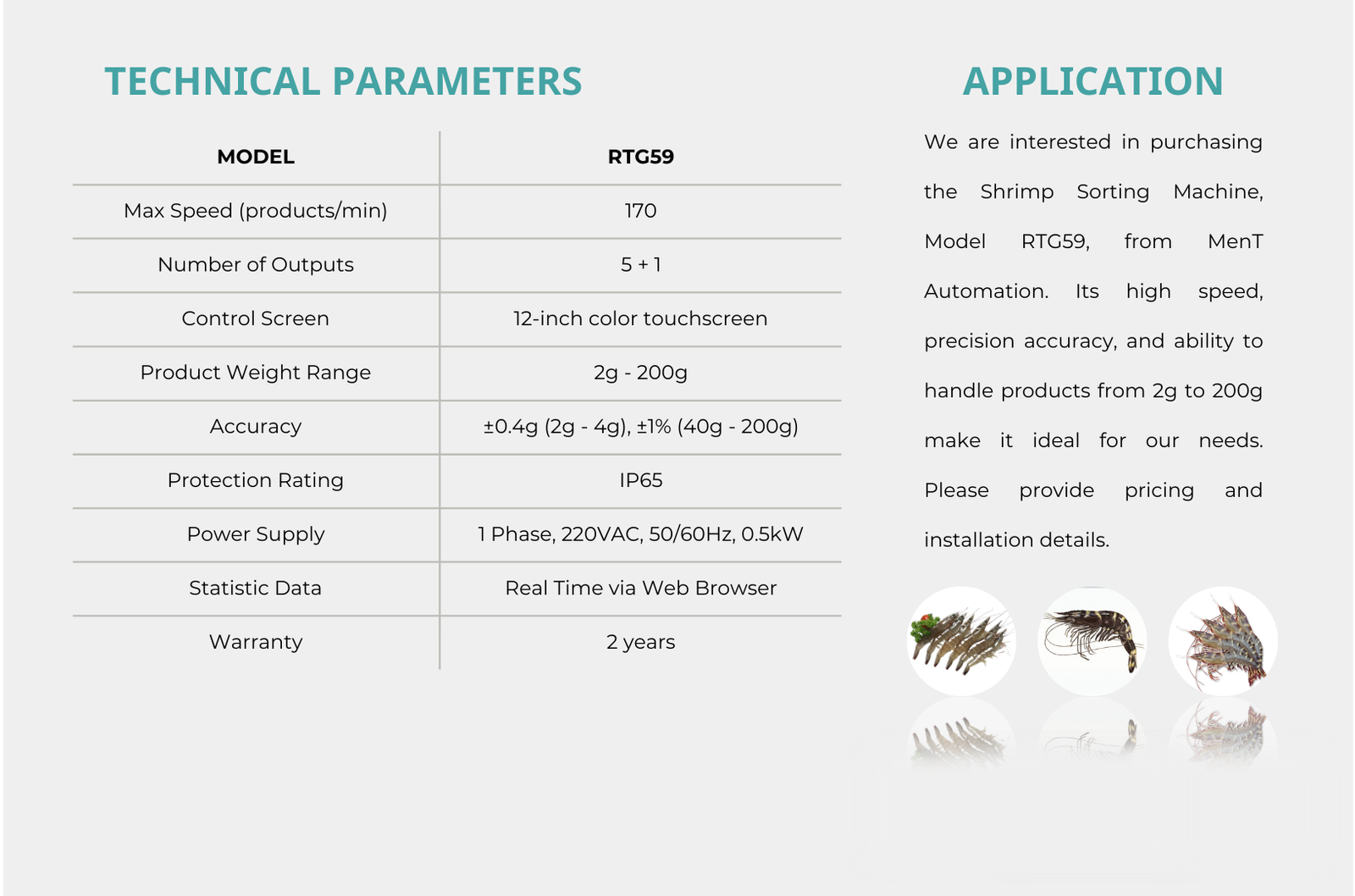

Shrimp Sorting Machine Specification

Wide Sorting Range, High Efficiency & Durable Design of

The machine handles a wide product range—from 2g to 200g—making it suitable not only for shrimp but also for small fish fillets and similar products. Accuracy is a key advantage of the RTG59:

±0.4g for products from 2g to 4g

±1% accuracy for items between 40g and 200g

Energy-Efficient & Fully Integratable Shrimp Sorting Machine

Despite its robust performance, the machine remains energy-efficient. It operates on a single-phase 220VAC power supply and consumes only 0.5 kW, helping facilities reduce operating costs while maintaining high productivity.

The RTG59 integrates seamlessly with a wide range of MenT Automation’s advanced processing systems, enabling factories to build a fully connected and highly efficient production ecosystem. When paired with our weighing conveyors, the RTG59 ensures precise product flow management and stable feeding conditions, helping the sorting process maintain consistent speed and accuracy even during peak operation. In addition, the system works smoothly with our productivity scale systems, allowing factories to collect real-time production data, monitor performance statistics, and optimize line efficiency with actionable insights.