MENT AUTOMATION – High-Precision Weighing Systems Expert

Welcome to MENT AUTOMATION, a global leader in developing high-accuracy weighing systems for the seafood and food-processing industry. With years of engineering experience and continuous improvement, we design weighing solutions that deliver exceptional precision, stability, and long-term reliability. Because of our strict R&D and testing standards, each product takes nearly two years to perfect before reaching our customers.

Our advanced weighing systems use digital load cells instead of analog ones. As a result, they eliminate noise, increase accuracy, and ensure stable performance in harsh factory environments. Moreover, our combination weighing systems boost productivity, reduce labor, and save more than 30 tons of product per year. In addition, our sorting and classification systems help factories maintain precise weight control, reducing both shortages and overfills. With real-time statistical software, operators can adjust their canning lines more easily and reduce giveaways by up to 60 tons during the warranty period.

Our advanced weighing systems use digital load cells instead of analog ones. As a result, they eliminate noise, increase accuracy, and ensure stable performance in harsh factory environments. Moreover, our combination weighing systems boost productivity, reduce labor, and save more than 30 tons of product per year. In addition, our sorting and classification systems help factories maintain precise weight control, reducing both shortages and overfills. With real-time statistical software, operators can adjust their canning lines more easily and reduce giveaways by up to 60 tons during the warranty period.

Why Choose MENT AUTOMATION weighing systems?

1. Precision and Reliability

Our weighing systems are engineered with high-quality components for exceptional accuracy. In addition, advanced digital load-cell technology ensures consistent and repeatable results.

2. Increased Productivity

Because our combination weighing systems automate the weighing process, factories achieve higher speed and reduced labor. This leads to faster output and improved efficiency.

3. Strong Quality Control

Our grading and sorting solutions allow operators to maintain tight control over each production stage. Therefore, product uniformity and quality remain stable throughout the process.

4. Real-Time Insights

Our software provides clear, real-time data. As a result, production leaders can make accurate adjustments and improve the performance of weighing systems quickly.

5. Expertise and Support

With many years of experience, our engineering team offers professional guidance and fast technical support. Additionally, we ensure minimal downtime and smooth daily operation.

Experience the MENT AUTOMATION Weighing SystemsAdvantage

By choosing MENT AUTOMATION, you gain advanced systems that improve accuracy, productivity, and long-term performance. Contact us today to schedule a consultation and discover how our weighing technologies can elevate your factory to a new level of efficiency.

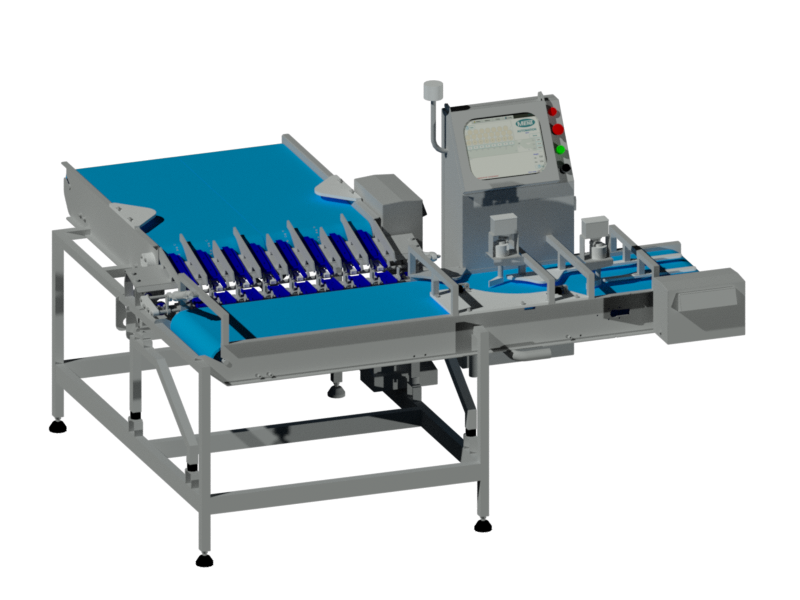

Combination Weigher

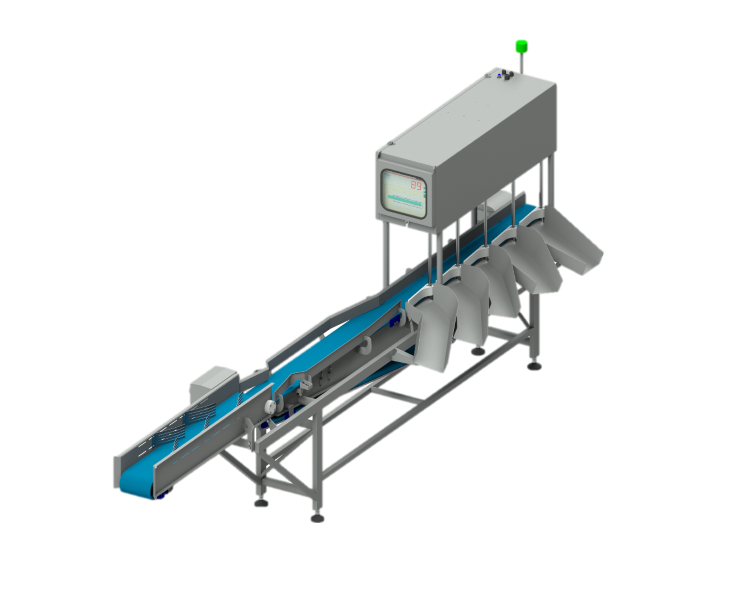

Canned Checkweigher

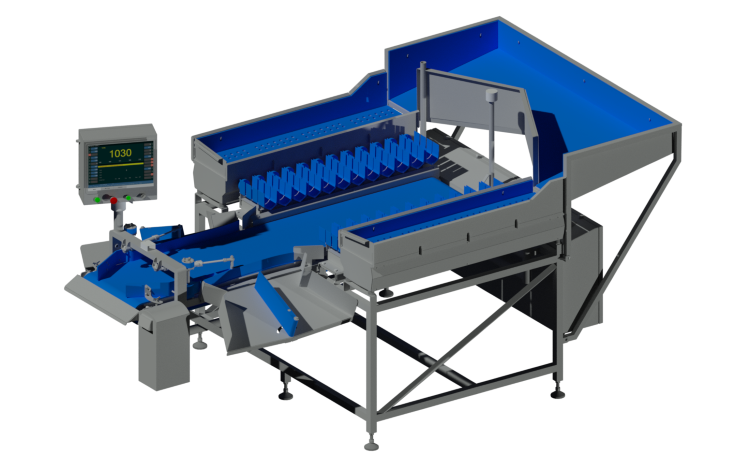

Grader