Tuna Injection Systems –Advanced CO & Brine Solutions for Tuna Processing

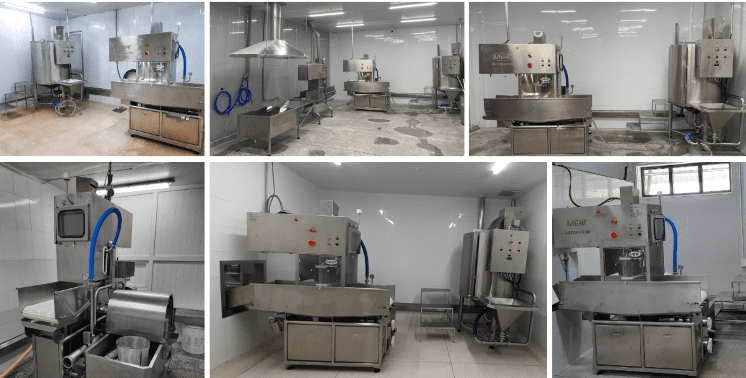

Tuna injection systems play a crucial role in today’s seafood processing industry, helping producers enhance color, flavor, texture, and preservation of tuna loins. Ment Automation Co., Ltd. proudly introduces its advanced solutions through two specialized machines: the Tuna Smoke Injection Machine and the Tuna Brine Injection Machine. These tuna injection systems are engineered to deliver superior performance, ensuring consistent quality and efficiency for modern tuna processors worldwide.

What Are Tuna Injection Systems?

TWe refer to automated machines that inject controlled amounts of CO smoke or vitamin-infused brine into tuna loins. This process helps maintain freshness, improve color stability, enhance taste, and optimize product texture. As global demand for premium tuna continues to rise, tuna processors increasingly rely on these systems to achieve uniform product quality, higher yields, and reduced manual workload.

Tuna Injection Systems for CO Smoke Enhancement

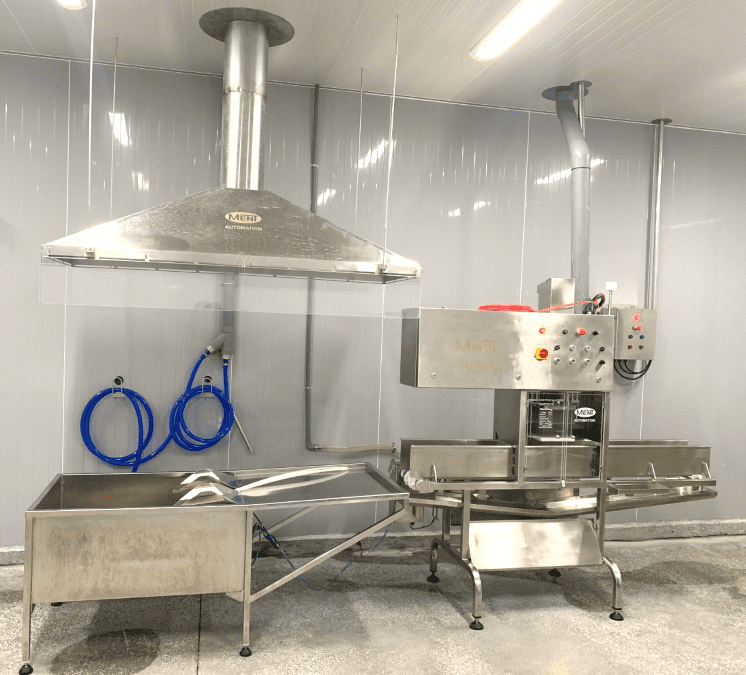

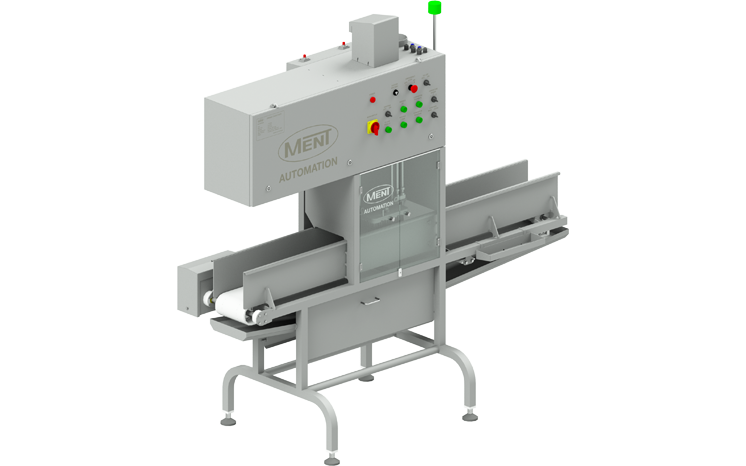

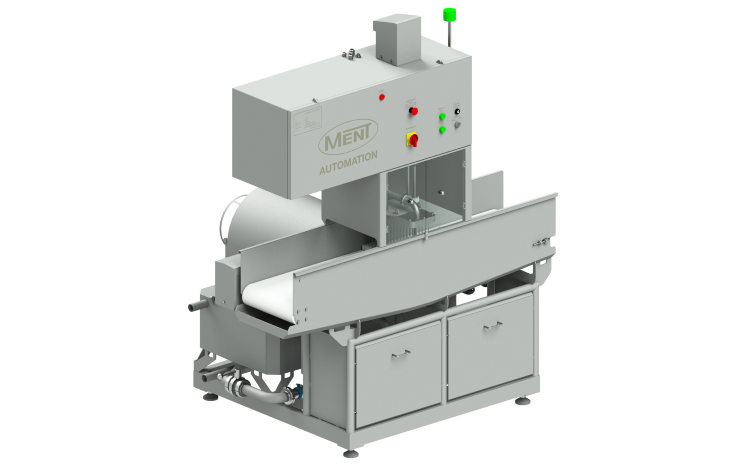

Tuna Smoke Injection Machine (CO Injection System)

The Tuna Smoke Injection Machine is a core component of modern tuna injection systems. Designed to enhance the natural color and flavor of tuna loins, this machine uses CO smoke, tasteless smoke, or clear smoke to intensify color without altering the natural taste of the fish. This technology produces a more vibrant and appealing tuna loin—highly desirable in export markets where appearance strongly influences consumer preference.

Consistent Color Penetration

One of the biggest challenges in tuna processing is achieving uniform color. This smoke-based tuna injection system ensures deep and even smoke penetration throughout the loin. The result is a product with consistent color, flavor stability, and higher commercial value. Uniformity across batches is essential for brands aiming to maintain a premium reputation.

Eco-Friendly & Efficient Operation

Ment Automation’s CO-based tuna injection systems are developed with sustainability in mind. An efficient smoke-generation system minimizes waste and reduces resource consumption. By using controlled CO output, the machine reduces smoke exposure for operators, creating a safer working environment while lowering environmental impact.

Stronger Branding for Premium Markets

Because this tuna injection system consistently produces high-quality, visually appealing tuna, seafood brands benefit from improved reliability and customer satisfaction. Maintaining consistent product quality directly strengthens brand identity in competitive markets.

Tuna Injection Systems for Brine & Vitamin Enhancement

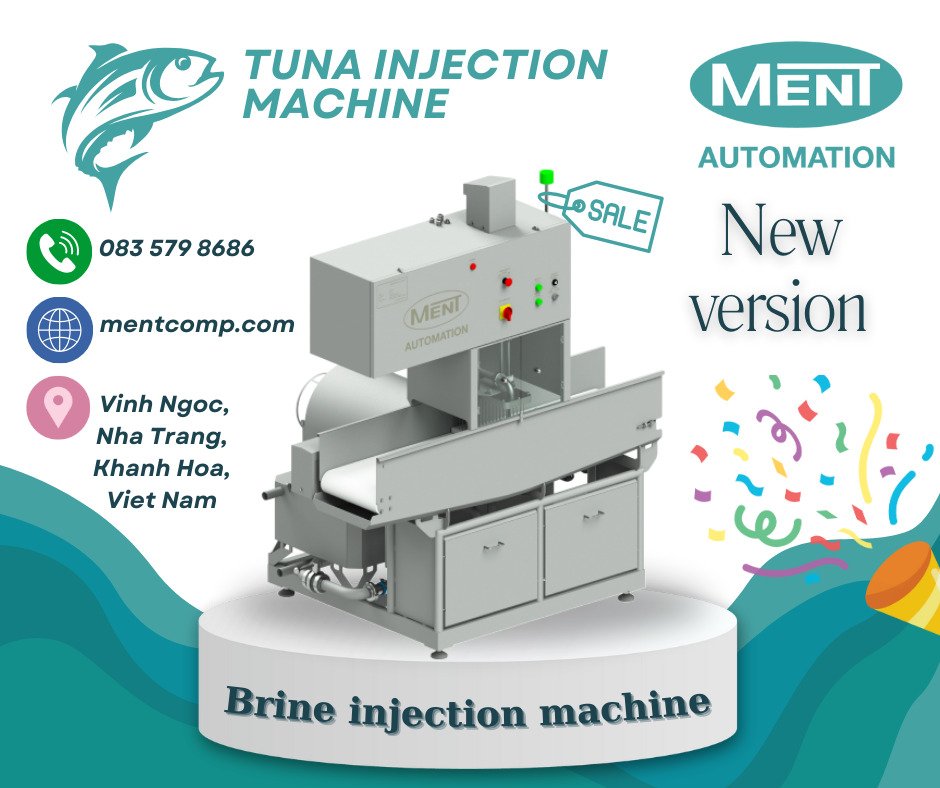

Tuna Brine Injection Machine (Vitamin Injection System)

The Tuna Brine Injection Machine is another crucial component of professional tuna injection systems. This advanced equipment injects a vitamin-rich brine solution directly into the tuna loin, improving its color, texture, and moisture-retention properties. The result is frozen tuna with enhanced visual appeal, better flavor, and improved nutritional value.

Precise Moisture & Color Control

The machine’s sophisticated injection mechanism ensures precise control over brine levels. This avoids issues like oversalting or excess water while achieving the desired color enhancement. The system stabilizes the natural red hue of tuna, making the product more appealing in international markets.

Nutritional Enhancement Through Vitamin Infusion

Unlike basic brine injection equipment, this tuna injection system incorporates vitamin infusion, adding valuable nutrients to tuna products. This feature is especially appealing in health-conscious markets, where consumers seek seafood that offers both flavor and nutritional benefits.

High Hygiene Standards

All parts in contact with brine are manufactured using high-quality stainless steel, ensuring corrosion resistance and easy cleaning. This hygienic design supports global food safety regulations, giving processors confidence in every production cycle.

Benefits of Using Tuna Injection Systems

Higher Productivity & Reduced Manual Labor

Both smoke and brine-based tuna injection systems significantly reduce manual processing time. Their automated cycles allow workers to focus on other production tasks, improving overall factory efficiency.

Consistency Across All Batches

Tuna processors benefit from consistent injection speed, pressure control, and solution distribution. These factors ensure uniform quality—an essential requirement for export markets.

Lower Operating Costs

Efficient resource usage means lower CO consumption, reduced brine waste, and minimized downtime. These advantages help processors reduce operational expenses while maintaining high production output.

User-Friendly & Low Maintenance

Ment Automation designs its tuna injection systems with intuitive controls, self-diagnostic alerts, and automated cleaning cycles. Operators can easily manage daily production without requiring advanced technical skills.

Why Choose Ment Automation’s Tuna Injection Systems?

Ment Automation’s expertise in seafood processing equipment makes its tuna injection systems reliable, efficient, and globally trusted. The company focuses on delivering:

Consistent product quality

Stable performance for high-volume production

Precision technology for CO and brine injection

Hygienic design compliant with global standards

Long-lasting components and easy maintenance

These advantages help processors meet rising global demand for premium tuna while maintaining competitive production costs.

Conclusion

Ment Automation Co., Ltd.’s tuna injection systems—including the Tuna Smoke Injection Machine and the Tuna Brine Injection Machine—are revolutionizing the modern tuna processing industry. These advanced systems enhance the color, flavor, moisture, texture, and nutritional value of tuna loins, providing seafood producers with reliable tools to consistently meet the highest global quality standards. By using controlled CO smoke or vitamin-enriched brine solutions, these machines ensure uniform injection, resulting in visually appealing, flavorful, and nutritionally fortified tuna products. As demand for premium tuna continues to grow worldwide, adopting these tuna injection systems allows processors to reduce labor costs, improve production efficiency, minimize waste, and maintain hygiene and safety standards. Furthermore, these technologies support scalability, helping companies expand their operations, strengthen brand reputation, and compete effectively in the increasingly competitive international seafood market, all while maintaining sustainable and environmentally friendly practices.