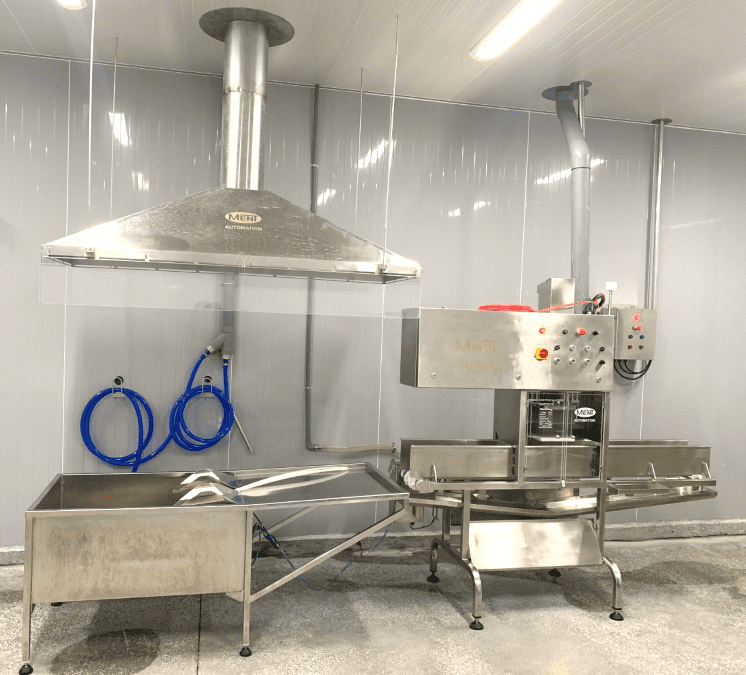

Smoke Injection Machine from Ment Automation Co., Ltd.

The Smoke Injection Machine from Ment Automation Co., Ltd. represents over 10 years of dedicated development, innovation, and precision engineering. As a global leader in CO-based tuna processing technology, we proudly export our Tuna Smoke Injection Machine to more than 20 countries and territories. With this advanced smoke injection system, tuna processors can significantly improve product quality, stabilize production output, reduce labor requirements, and ensure maximum safety for operators.

Advanced Technology for Superior Tuna Quality

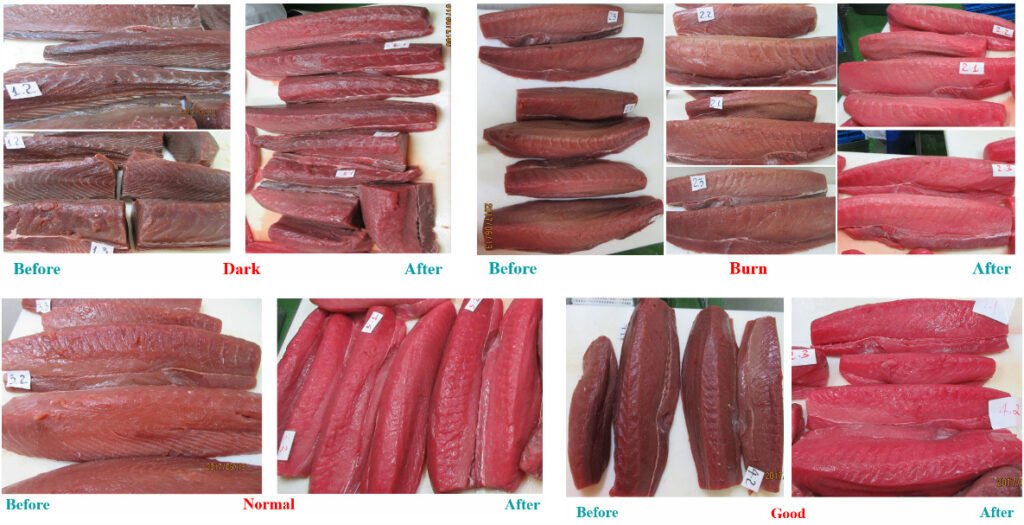

Our Smoke Injection Machine uses cutting-edge CO injection technology to deliver a controlled, accurate, and safe amount of CO into each tuna loin. As a result, the tuna achieves a vibrant color, improved texture, and enhanced flavor. Moreover, this technology minimizes oxidation, reduces spoilage, and extends the overall shelf life of the product.

To explore other related technologies, you may also visit:

Key Features of Our Smoke Injection Machine

Precision CO Injection

The Smoke Injection Machine delivers the exact amount of CO required for optimal results. Consequently, processors maintain consistent quality without compromising food safety.Enhanced Operator Safety

Our equipment includes multiple layers of safety systems. Therefore, users can operate the Smoke Injection Machine with confidence, even during high-volume production.Efficiency and Cost Reduction

Because the injection process is fully automated, tuna factories can reduce manual labor, speed up production, and lower their operating costs.Global Reach and Proven Technology

As the only company exporting CO-based smoke injection machines for tuna to over 20 countries, Ment Automation has built a strong reputation for reliability and performance.

Benefits for Tuna Processors

Improved Product Quality

Ours Machine enhances color retention, texture, and flavor, resulting in premium-quality tuna.Extended Shelf Life

Since CO reduces oxidation, the injected tuna maintains freshness for a longer period during storage and transport.Higher Productivity

Automation eliminates processing inconsistencies while significantly boosting production speed.Cost Savings

With reduced labor and minimized product loss, processors benefit from long-term savings and better operational efficiency.

By investing from Ment Automation Co., Ltd., you are choosing a partner committed to enhancing your production quality, safety, and efficiency. Join the global community of satisfied clients and take your tuna processing to the next level.