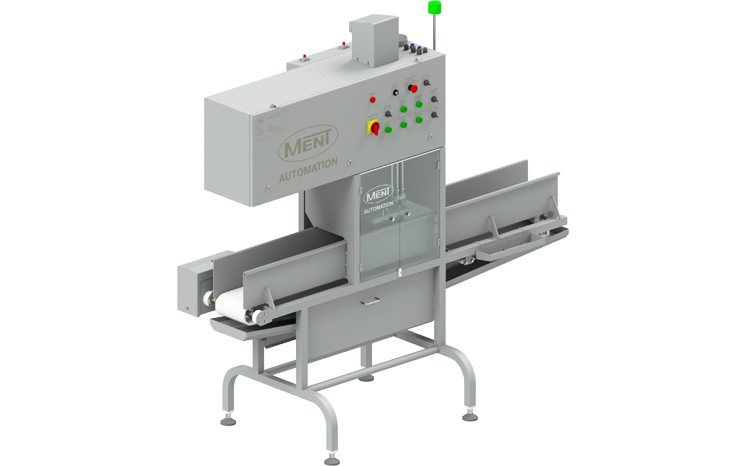

Tuna Injection Machine for Modern Seafood Processing

A Tuna Injection Machine is one of the most essential technologies used in modern professional seafood factories. At MenT Automation, we design and manufacture advanced Tuna Injection Machines that enable processors to achieve consistent product quality, superior color retention, and higher production efficiency. These machines are specifically engineered to handle different species of tuna, ensuring that each loin receives the precise amount of brine or CO smoke needed for optimal appearance, flavor, and texture.

About MenT Automation and Tuna Injection Machine Expertise

Founded in 2014 in Nha Trang, Vietnam, MenT Automation has grown steadily into a leading global supplier of advanced seafood processing machinery. Over the years, we have earned a reputation for delivering high-quality equipment that meets the rigorous demands of modern industrial operations. Throughout our development, MenT Automation has remained committed to engineering precision, long-term durability, and innovative design features that address the specific needs of seafood processors.

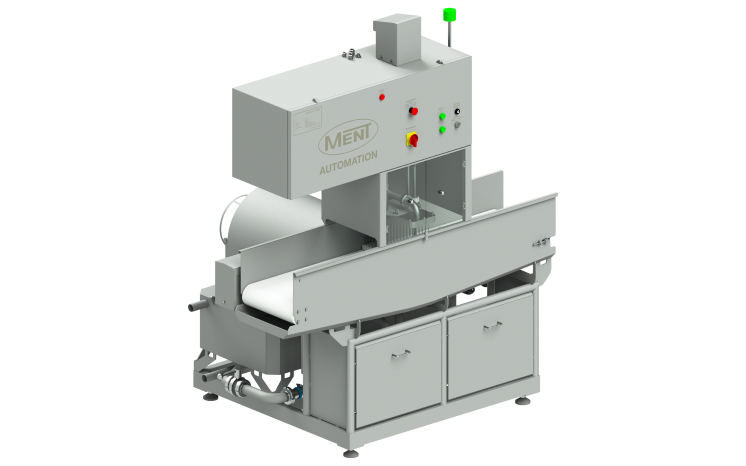

Complete In-House Manufacturing of Tuna Injection Machines

At MenT Automation, every Tuna Injection Machine is built with complete in-house manufacturing. Our facilities include CNC machining, PCB fabrication, R&D labs, electrical assembly, and strict quality control inspections. As a result, every machine meets international standards for durability and performance. Moreover, in-house production allows us to customize solutions based on specific factory layouts, injection requirements, or production volume. Consequently, seafood processors receive equipment tailored to their operational needs while benefiting from MenT Automation’s commitment to quality.

Comprehensive Seafood Processing Solutions with Tuna Injection Machines

MenT Automation provides machinery for tuna, pelagic species, and various seafood applications. While each machine serves a specialized role, all are designed to enhance factory productivity, consistency, and labor efficiency. By integrating a Tuna Injection Machine, producers can ensure even color, moisture, and nutritional quality for tuna loins. Furthermore, these systems are compatible with both brine (vitamin) and CO smoke injection methods, offering versatile solutions for modern seafood factories.

Our Customers

Commitment to Excellence

At MenT Automation, our commitment to excellence drives everything we do. From designing advanced Tuna Injection Machines to ensuring rigorous quality control, we strive to deliver equipment that meets the highest standards of performance and reliability. Our team continuously researches and develops new technologies, ensuring that every machine we produce not only meets but exceeds customer expectations. Reach out to us today to experience our dedication to innovation and superior service.

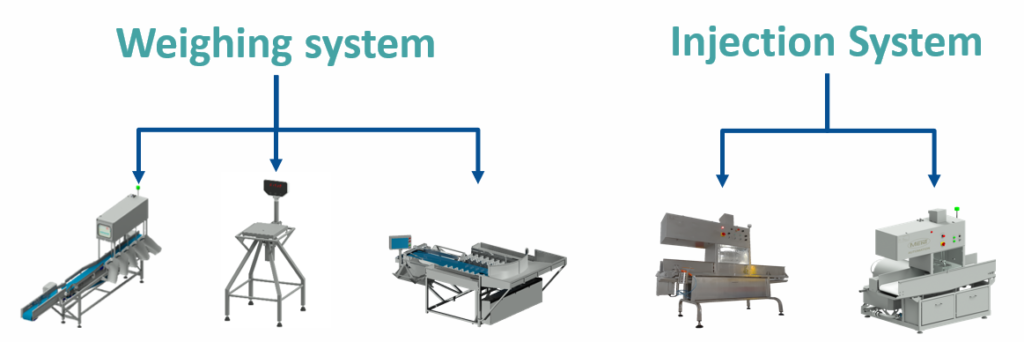

Our Main Product Lines

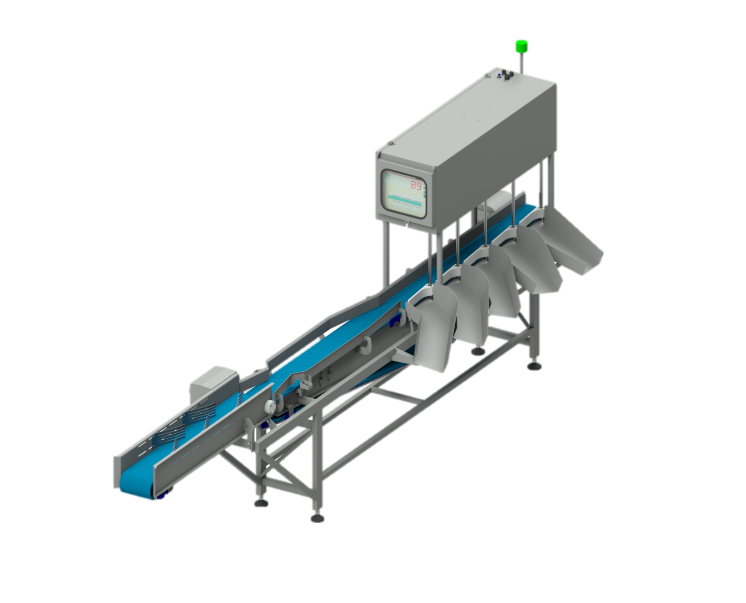

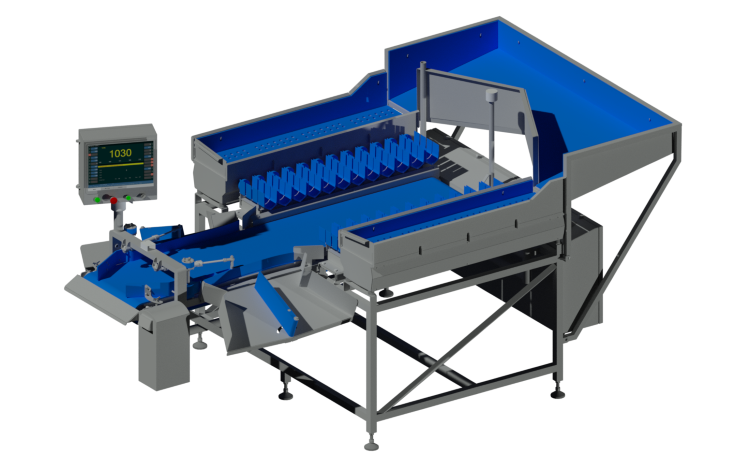

Weighing Systems

Tuna Injection Machine

Innovations in Tuna Injection Machine Technology

MenT Automation continues to advance Tuna Injection Machine technology through enhanced precision, stronger hygiene control, and intelligent monitoring systems. Key features include:

Real-time control interface for easy operation

Precise needle distribution to ensure uniform injection

Food-grade stainless steel SS304/316 for hygiene and durability

Stable injection performance for consistent results

Reduced maintenance costs and downtime

These innovations make our Tuna Injection Machines ideal for factories seeking efficient, reliable, and safe tuna processing solutions.

Enhancing Tuna Quality with Injection Systems

A Tuna Injection Machine ensures every tuna loin achieves consistent color, texture, and moisture. By using precise brine or CO smoke injection, seafood factories can produce visually appealing and flavorful products that meet international standards.

Advanced Technology for Modern Processing of Tuna injection machine

MenT Automation’s Tuna Injection Machines use state-of-the-art needle distribution and real-time monitoring. This ensures uniform injection, optimized nutrient retention, and enhanced shelf life for tuna, giving processors a competitive advantage in global markets.

Reliable and Hygienic Design of Tuna injection machine

Constructed with food-grade stainless steel, MenT Automation’s Tuna Injection Machines are easy to clean and maintain. Their durable and hygienic design ensures safety, reduces downtime, and supports sustainable seafood processing operations

Custom Solutions for Every Factory of Tuna injection machine

Whether for small-scale operations or industrial production, Tuna Injection Machines can be tailored to fit any factory layout. MenT Automation provides custom configurations that meet specific production goals while optimizing workflow efficiency.

Precision Control for Consistent Results of Tuna injection machine

MenT Automation’s Tuna Injection Machines feature precise control over injection speed, needle placement, and solution volume. This level of precision ensures every tuna loin receives the exact amount of brine or CO smoke, resulting in uniform color, flavor, and texture throughout each batch.

Reducing Waste and Increasing Profitability of Tuna injection machine

By using advanced Tuna Injection Machines, seafood factories can reduce over-injection, minimize waste, and maintain consistent product quality. This not only improves profitability but also supports sustainable production practices, making factories more environmentally responsible.

Supporting Nutritional Enhancement of Tuna injection machine

The brine injection function in MenT Automation’s Tuna Injection Machines allows for vitamin enrichment, adding nutritional value to tuna loins. This feature ensures that the final product is healthier for consumers while maintaining moisture and enhancing flavor.

Why Tuna Factories Choose MenT Automation

- Over 10 years of engineering experience

Machines deployed in 20+ countries

Strong global technical support

Durable stainless-steel construction

Custom-built systems for any factory layout

Contact Us for Expert Support

If your factory needs a more efficient processing workflow or faces tuning issues with injection precision, our engineering team is ready to help. Let us provide a customized Tuna Injection Machine solution that fits your production requirements.